Industrial Pallet Racking | Storage Racking | Racking Inspections | Dexion Solutions

Ongoing safety for your space

Book your Pallet racking inspection today

Pallet Racking Inspections & Safety Audits – Why They Matter

At Cemac, we help warehouses and industrial sites across the Waikato stay safe, compliant and efficient through professional pallet racking inspections. As a supplier and installer of Dexion racking systems, we ensure your storage infrastructure meets the latest safety standards and performs reliably year-round.

Whether you operate a high-density warehouse, retail distribution centre or manufacturing facility, regular racking inspections are essential for protecting your staff, stock, and business.

Pallet Racking Inspections & Safety Audits – Why They Matter

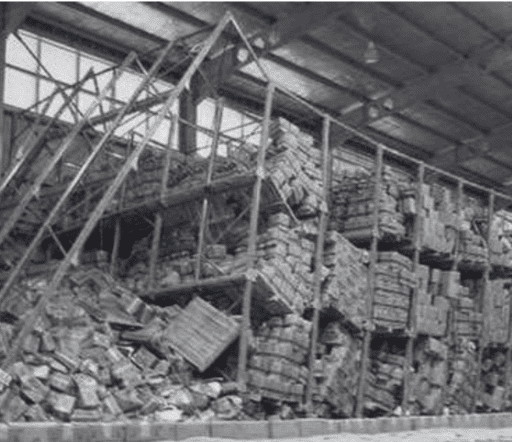

Damage to pallet racking isn’t always obvious — yet even small bends, missing safety clips or overloaded bays can lead to failures, injuries and costly downtime.

A professional inspection helps you:

- Prevent collapses or structural failures

- Comply with AS4084.2.2023 (formerly AS/NZS 4084)

- Meet WorkSafe NZ expectations for warehouse safety

- Identify impact damage early

- Maintain Dexion racking performance and lifespan

- Avoid expensive repairs or shutdowns

For any business storing palletised goods, annual inspections are not optional — they are an essential safety requirement.

What’s Included in a Cemac Racking Inspection

At Cemac, our qualified inspectors carry out a comprehensive, top-to-bottom audit of your Dexion or compatible racking system. We examine uprights and frames for dents, bends, rust, cracks, twisting, or impact damage, and ensure all beams, connectors, and safety clips are secure and undamaged. Baseplates and anchor bolts are checked to confirm they are tight, stable, and compliant with Dexion’s engineering specifications. Every bay is reviewed to verify clear and visible load capacity signage, in line with WorkSafe requirements. We also assess pallet condition and loading practices, identifying broken pallets, uneven weight distribution, or poor stacking that could compromise safety. Areas prone to forklift impacts, particularly aisle ends, are inspected for damage, while environmental factors such as floor level, seismic movement, moisture, corrosion, and ground fixing are considered. Following the inspection, you receive a detailed written report highlighting risks, recommended corrective actions, and compliance notes. This process is fully aligned with the AS4084.2.2023 racking standard, WorkSafe NZ guidance, and Dexion manufacturer specifications.

Why Choose Cemac for Your Racking Inspection?

Dexion Racking Specialists

As a fit-out and racking provider in Waikato using genuine Dexion industrial systems, we understand the engineering behind your racks — not just the surface-level issues.

Compliant, Competent Inspectors

Our inspectors meet the competency requirements of AS4084.2.2023 and provide fully documented assessments.

Independent, Safety-First Approach

We focus purely on identifying risks and keeping your business safe — not upselling parts you don’t need.

Local Support Across Waikato

Fast response times, local knowledge and long-term relationships with industrial clients.

How Often Should Pallet Racking Be Inspected?

Under AS4084.2.2023, warehouses must complete:

- Annual professional inspections by a competent, external provider (like Cemac), and

- Regular in-house visual checks for obvious damage, missing clips, or forklift impacts.

If your warehouse has:

- high forklift traffic

- heavy or uneven loads

- narrow aisles

- previous rack damage

- seismic activity or ground movement

… then more frequent inspections are recommended.

Book your inspection today

Our Simple, Proven Inspection Process

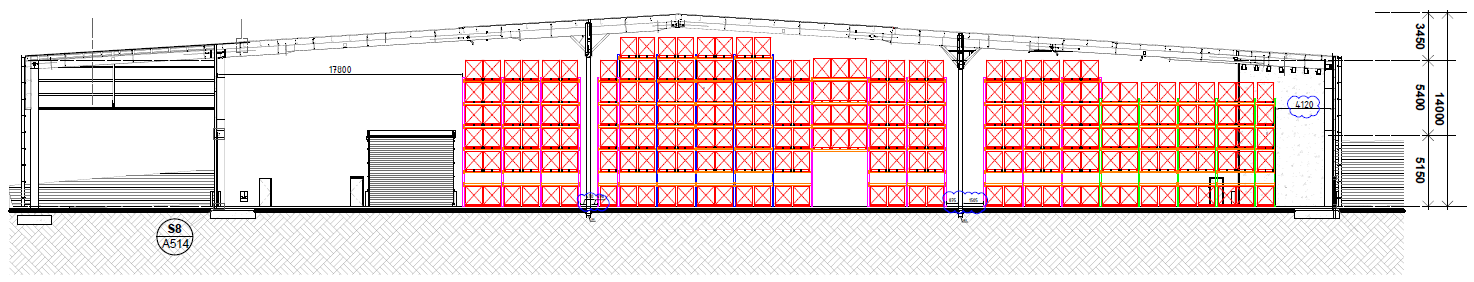

We begin with a full assessment of your warehouse, mapping out your Dexion racking system and overall layout. This gives us a clear understanding of your storage configuration, load patterns and any high-risk areas before the inspection begins.

Every bay is examined in detail according to the AS4084.2.2023 racking standard. We check beams, uprights, anchors, load signage, pallets and environmental factors to ensure your racking system is structurally sound and compliant.

All identified issues are categorised using a simple green, amber and red risk-rating system. This helps you instantly understand which areas are safe, which require monitoring, and which need immediate attention.

You receive a clear, visual report that includes photos, descriptions and recommended actions for each finding. This documentation supports WorkSafe compliance and gives you a reliable reference for future maintenance.

Once the inspection is complete, we guide you through the next steps, whether that involves replacing damaged components, improving loading practices or scheduling future checks, so your racking remains safe, compliant and efficient.

How Racking Inspections Improve Warehouse Efficiency

- Reduce downtime by preventing sudden failures

- Maintain smoother forklift flow and pallet handling

- Reduce stock losses

- Maintain Dexion racking warranty conditions

- Extend the lifespan of your entire racking system

- Improve Health & Safety compliance documentation Increase staff confidence and reduce incident risks

Safety isn’t just compliance — it’s operational efficiency.

Frequently Asked Questions

Do I legally need pallet racking inspections?

While not explicitly written into NZ law, WorkSafe expects compliance with recognised standards. AS4084.2.2023 requires annual inspections by a competent external provider.

Can my staff do the inspection instead?

Internal checks are good for spotting obvious damage, but a formal inspection must be external and competent.

Do you inspect non-Dexion racking?

Yes. We inspect Dexion and compatible racking systems across the Waikato region.

What if repairs are needed?

We provide clear recommendations. If replacement parts are needed, we advise you on compatible, compliant options.