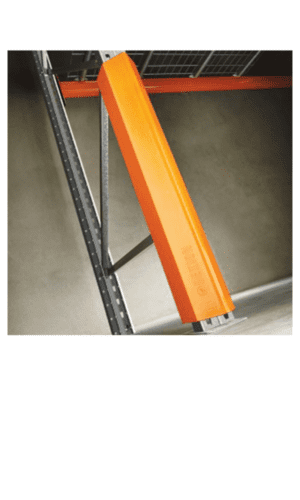

Flow Through Racking

Flow Through Racking

Fast throughput with automated stock rotation

Flow Through Racking, also known as Pallet Flow Racking, provides a highly efficient storage system that ensures first-in, first-out (FIFO) rotation. Pallets are loaded at one end and retrieved from the other, creating a continuous, intuitive product flow.

This system is perfect for operations handling large batch SKUs or requiring buffer storage between production, goods reception, and dispatch. With gravity-fed roller lanes, stock is automatically rotated without the need for forklift entry into the racking, improving both safety and efficiency.

Key Features:

-

Very dense storage capacity, especially effective with limited SKUs and high pallet volumes

-

FIFO stock rotation guaranteed — ideal for products with shelf life or strict rotation needs

-

Safe handling — forklifts do not need to enter the rack structure

-

Supports high throughput with continuous product flow

-

Wide range of pallet types can be accommodated when designed correctly

-

Stable, consistent pallet loads are mandatory for performance

-

Designed and tested in accordance with EN 15512:2009 (formerly FEM)

Please contact our Sales Team for more information on this product