We make it easy for your business to meet essential safety regulatory standards.

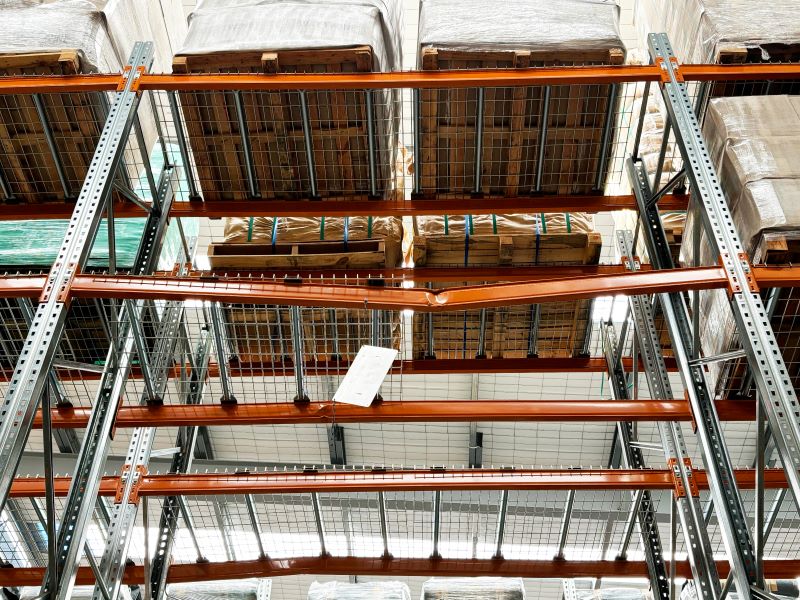

Our Dexion approved rack inspectors can examine your installation and provide you with a written report, including any adjustments that may be required. Incorporating annual rack inspections, rack protection, and safety products like mesh decks enhances workplace safety and minimises the risk of inventory damage or downtime due to equipment failure.

- Will you risk damaging inventory due to uninspected racking?

- Why compromise the safety of your staff by neglecting regular racking inspections?

- Can your business afford the downtime caused by preventable racking failures?

- Is avoiding the cost of inspections worth the potential legal consequences?

“Regular racking inspections are crucial for maintaining a safe and efficient workplace. By identifying potential issues early, you prevent accidents, protect your inventory, and ensure compliance with safety regulations. Don’t wait for an accident, inspections safeguard both your employees and your assets” – Paul Jones, Director and Industrial Sales

Dexion racking systems are engineered for durability, but regular inspections are essential to maintain safety and operational efficiency. Here’s why inspections are crucial:

- Preventative Maintenance: Constant loading and unloading can compromise the integrity of racking systems over time. Inspections help identify signs of wear and tear before they escalate into safety hazards.

- Legal Compliance: Regulatory standards mandate that companies ensure a safe working environment for employees and maintain equipment in good condition. Failure to comply can lead to legal consequences and reputational damage.

- Risk Mitigation: Inspections help prevent accidents, injuries, and damage to goods by identifying and addressing potential risks early on.

- Peace of Mind: Comprehensive inspections provide a thorough assessment of racking components, highlighting areas for repair or reinforcement. This ensures peace of mind for both employees and management.

Our Rack Inspection service offers:

- Inspections should be conducted at intervals not exceeding 12 months by competent inspectors. However, additional inspections can be scheduled based on the company’s preference.

- Detailed reports categorising damage severity using a traffic light system.

- Green: Negligible damage.

- Amber: Requires repairs but not immediate off-loading.

- Red: Severe damage requiring immediate action.

- Load signs indicating maximum capacity for each rack.

- Advice on weekly inspections.

- Standard that governs Pallet racking AS4084/2023

The Crucial Role Of Pallet Racking Inspections

New Zealand’s seismic activity underscores the importance of regular inspections for racking systems. Earthquakes pose additional risks, making inspections vital for safety management. Worksafe NZ recommends annual inspections to mitigate the impact of potential damage and ensure compliance with regulations.

Why not ensure peace of mind by having competent inspectors evaluate your racking?

Get in touch today

Phone: 078395145

Email: info@cemac.nz

Website: cemac.nz